When it comes to constructing durable and efficient assemblies, selecting the right fasteners can make all the difference. Among the myriad options available, the best flat thread forming screws stand out for their unique design and exceptional performance. These innovative screws are engineered to create threads in pre-drilled holes, resulting in strong, vibration-resistant joints that can withstand the rigors of various applications. Whether you’re working on a DIY home improvement project or tackling industrial manufacturing tasks, the right choice in flat thread forming screws can significantly enhance the integrity and longevity of your assembly.

In this comprehensive guide, we delve into the world of flat thread forming screws, exploring their unique benefits, key features, and the top products currently available on the market. With insights gained from extensive reviews and expert recommendations, we aim to equip you with the knowledge necessary to make an informed decision. By understanding the characteristics that define the best flat thread forming screws, you can ensure that your projects not only meet but exceed expectations in terms of quality and durability.

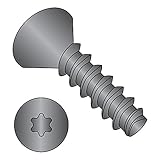

Before we start our review of the best flat thread forming screws, here are some related products you can find on Amazon:

Overview of Flat Thread Forming Screws

Flat thread forming screws are a specialized type of fastener designed to create their own threads as they are driven into materials, typically plastics and softer metals. Unlike traditional screws that cut threads into the substrate, these innovative screws have unique geometries that displace material, allowing for strong, secure fastening without pre-drilled holes. This attribute makes them particularly advantageous for assembly processes where speed and efficiency are essential.

The primary benefit of using flat thread forming screws is their ability to enhance the overall integrity of the assembly. When properly applied, they minimize the risk of thread stripping, ensuring that the fastener remains securely engaged over time. Additionally, because they form their own threads, they can reduce the need for additional tooling or equipment, thus streamlining the manufacturing process.

Flat thread forming screws can come in various sizes and materials, catering to a wide range of applications. Their design often includes a flat head which allows for a flush finish against the surface of the substrate, contributing to a neat and professional appearance. They are commonly used in industries such as automotive, electronics, and furniture, where reliability and aesthetics are crucial.

When searching for the best flat thread forming screws for your project, it is important to consider factors such as the type of material being fastened, load requirements, and environmental conditions. This ensures that you select a screw that not only meets your design specifications but also provides long-lasting performance and durability.

The Best Flat Thread Forming Screws

1. Oatey 33449 Flat Thread Forming Screw

The Oatey 33449 Flat Thread Forming Screw is a top choice for contractors and DIY enthusiasts alike. Built with a robust steel construction, these screws are designed to provide outstanding grip and durability. Their flat head aids in a flush finish, making them particularly useful for applications where aesthetics matter. Installation is straightforward, as the screws easily penetrate and form threads in a variety of materials, minimizing the risk of splitting.

Additionally, the corrosion-resistant coating ensures that these screws maintain their integrity over time, even when exposed to moisture. Users have praised their ability to handle heavy loads without sacrificing performance, which is essential for structural applications. Whether you’re working on plumbing, cabinetry, or metal fixtures, the Oatey 33449 delivers reliable results and a professional finish.

2. Hillman Group 60104 Flat Thread Forming Screw

The Hillman Group 60104 Flat Thread Forming Screw stands out for its excellent self-tapping capabilities. Designed specifically for metal and plastic applications, these screws offer a secure fastening solution that eliminates the need for pre-drilling. The flat head design allows for a sleek appearance while ensuring that the fasteners sit flush against the surface, which is a significant advantage for open installations.

Performance-wise, these screws are rated highly for their strength and resistance to stripping. Feedback from users highlights their efficiency in various projects, including electrical installations and metal fabrications. With their reliable thread-forming technology, the Hillman Group 60104 screws provide a solid grip in diverse materials, making them a dependable choice for both hobbyists and professionals.

3. FastenMaster FMPTFS Flat Thread Forming Screw

FastenMaster FMPTFS Flat Thread Forming Screws are engineered for superior performance in demanding environments. These high-strength screws are made from durable materials and feature a flat head for a discreet finish. Their unique thread design allows them to cut through wood and composite materials effortlessly, eliminating splitting while ensuring maximum holding power. This makes them an ideal choice for decking and other outdoor applications.

Users appreciate the ease of installation that comes with these screws, thanks to their self-drilling feature that negates the need for pilot holes. Furthermore, the screws are designed to withstand the elements, making them resistant to rust and corrosion. The FastenMaster FMPTFS is highly recommended for projects requiring long-lasting, sturdy fastening solutions that perform well under pressure.

4. Everbilt 44123 Flat Thread Forming Screw

The Everbilt 44123 Flat Thread Forming Screw is a versatile option that excels in various applications, from household repairs to more complex projects. Crafted with zinc-plated steel, these screws offer excellent corrosion resistance, making them suitable for indoor and outdoor use. Their flat head creates a clean appearance when installed, which is particularly beneficial for visible applications.

Users frequently report that the Everbilt 44123 screws are easy to drive in and provide a strong hold without the risk of stripping, thanks to their precise thread design. This combination of strength and aesthetic appeal makes them a valuable addition to any toolbox. Whether you’re fastening cabinets, fixtures, or furniture, the Everbilt 44123 delivers dependable performance and convenience.

5. Simpson Strong-Tie TFLF Flat Thread Forming Screw

Simpson Strong-Tie TFLF Flat Thread Forming Screws are known for their superior grip and reliability in structural applications. Made with high-quality steel and designed for maximum load-bearing capacity, these screws provide excellent performance across a wide range of materials, including wood, steel, and concrete. The flat head promotes a smooth finish, making them ideal for visible installations where appearance is key.

What sets the TFLF screws apart is their innovative thread design, which enhances resistance to pull-out and enhances overall stability. Users consistently rave about their ease of installation and fantastic reliability, especially in high-stress applications. The Simpson Strong-Tie TFLF is a preferred choice for contractors looking for screws that combine functionality with durability, ensuring that projects stand the test of time.

Why Do People Need to Buy Flat Thread Forming Screws?

Flat thread forming screws are essential in various industries primarily due to their efficiency and durability. Unlike traditional screws that create a hole for threading, flat thread forming screws displace material to form threads. This unique characteristic allows for a tighter grip in the material, which is particularly beneficial when working with softer metals, plastics, or composite materials. By purchasing these screws, users can enhance the overall longevity of their assembled products while minimizing the risk of stripping or loosening.

The need for flat thread forming screws also stems from their versatility. They can be utilized in a wide range of applications, from automotive assembly to electronics. Their flat head design offers a low-profile look, making them suitable for applications where aesthetic appeal is crucial. This versatility means that manufacturers and hobbyists alike benefit from having a reliable supply of the best flat thread forming screws on hand, tailored to meet the specific requirements of their projects.

Another key reason for choosing flat thread forming screws is the ease of installation they provide. These screws are designed to cut into the material seamlessly, allowing for a quicker assembly process with fewer complications. This advantage not only saves time but also reduces labor costs, ultimately benefiting businesses in a competitive market. Professionals value tools and materials that streamline their workflow, and flat thread forming screws certainly deliver on this front.

Finally, the ability to maintain tight connections over time is another compelling reason to consider flat thread forming screws. Their design minimizes the risk of loosening due to vibrations or mechanical stress, which is often a concern in automotive or machinery applications. By investing in flat thread forming screws, individuals and businesses can ensure that their products are built to last, providing reassurance and reliability in their final outcomes.

Types of Flat Thread Forming Screws

Flat thread forming screws come in various types designed for specific applications and materials. Understanding these types is crucial for choosing the right screw for your project. Some common types include self-tapping screws, which can create their own thread in the material, and machine screws, which require a pre-formed hole. The head styles vary too, including flat, pan, and hex heads, each suitable for different fastening needs.

Self-tapping screws are particularly useful when working with softer materials like plastics or thin metals, as they can effortlessly form threads without pre-existing holes. Alternatively, machine screws are excellent for use with nuts or tapped holes in metal, providing strong and secure joints. Flat head screws are designed to sit flush with the surface of the material, making them ideal for applications where a smooth finish is required.

Another consideration is the material of the screws themselves. They can be made from a variety of materials, including stainless steel, carbon steel, or even specialized alloys designed for corrosion resistance. Choosing the right type and material is essential for ensuring the longevity and performance of your assembly.

Common Applications for Flat Thread Forming Screws

Flat thread forming screws are widely used across a variety of industries, showcasing their versatility and efficiency. One common application is in the automotive sector, where these screws are used to assemble body panels, trim pieces, and even engine components. The ability to form threads directly in the material allows for lightweight construction while maintaining strength.

In the electronics industry, flat thread forming screws are essential for securing components within devices such as computers and appliances. Their design minimizes the risk of damaging sensitive parts during installation, ensuring a reliable fit. Moreover, their ability to create a tight hold without the need for additional fasteners simplifies the manufacturing process.

The construction industry also benefits from the use of flat thread forming screws, particularly in structural assemblies and cabinetry. They enable fast and efficient assembly of various materials, such as wood and metal. These screws not only expedite the building process but also contribute to the durability and strength of the finished product, making them a preferred choice among contractors and builders.

Benefits of Using Flat Thread Forming Screws

Choosing flat thread forming screws offers numerous advantages that can enhance your projects. One significant benefit is their ability to provide a strong and efficient fastening solution. By forming their own threads, these screws can create a tight grip within the material, reducing the likelihood of loosening over time. This characteristic is particularly beneficial in high-vibration environments, where standard screws might fail.

Another advantage is the time-saving aspect of using flat thread forming screws. The fastening process is quicker since there’s no need to pre-drill holes for many applications. This not only accelerates production and assembly times but also minimizes labor costs, making them a cost-effective option for both small-scale and industrial applications.

Furthermore, flat thread forming screws contribute to a cleaner and more aesthetically pleasing end product. Their design allows for a smooth finish and reduced surface protrusion, which is appealing in visible applications. Additionally, their ability to create a snug fit means fewer gaps, resulting in better overall integrity and performance of the assembled item.

Maintenance and Care for Flat Thread Forming Screws

Proper maintenance and care for flat thread forming screws can significantly extend their lifespan and maintain the integrity of your assembly. After installation, it’s important to periodically check the screws for tightness, especially in applications subject to vibration or thermal expansion and contraction. Using a torque wrench for this purpose can prevent overtightening, which might damage the screw or the material it’s fastened to.

When cleaning around areas with flat thread forming screws, avoid using harsh chemicals that could corrode the screws—especially if they are made from materials such as stainless steel. Instead, opt for mild detergents and soft cleaning tools. Keeping the environment around the screws free from moisture and contaminants will also help prevent rust and degradation over time.

If you encounter any issues, such as stripped threads or a loose fit over time, consider replacing the screws with new ones rather than attempting to repair them. Regularly inspecting your assemblies not only ensures performance but also aids in detecting issues early on, ultimately saving time and effort in the long run. Proper care safeguards both the screws and the materials they secure, promoting longevity and reliability in your projects.

Buying Guide: Best Flat Thread Forming Screws

When it comes to selecting the best flat thread forming screws, several factors come into play to ensure you make an informed decision. These specialized screws are designed to create their own threads in materials, which can save time and improve the integrity of your assembly. In this guide, we’ll explore six essential factors to consider when choosing the right flat thread forming screws for your projects.

1. Material Composition

The material from which the screws are made plays a crucial role in their functionality and durability. Common materials include stainless steel, carbon steel, and nylon. Stainless steel screws are resistant to corrosion, making them ideal for outdoor applications or environments with high humidity. On the other hand, carbon steel screws are strong and provide excellent mechanical properties but may require additional coatings to protect against rust.

When selecting the best flat thread forming screws, you need to consider the environmental conditions they will face. For instance, if the screws are to be used in marine applications or other challenging environments, opting for marine-grade stainless steel screws would be advisable. Additionally, the composition can also affect the weight and cost, so it’s essential to find a balance that fits your budget while meeting the durability requirements for your specific application.

2. Thread Type

The thread type of flat thread forming screws is a determining factor in their performance. These screws typically feature either a coarse or fine thread design, and each type has its advantages. Coarse threads provide better grip and are more effective for assembling materials with lower density, while fine threads are ideal for applications requiring a tighter fastening in harder materials.

Moreover, the choice of thread type can impact the ease of installation. Coarse threads facilitate quicker assembly by engaging with the material faster, whereas fine threads tend to offer greater resistance to loosening over time. It’s vital to assess the materials you will be fastening together and choose the thread type that complements them to achieve the best fastening solution.

3. Screw Diameter and Length

Choosing the correct diameter and length of flat thread forming screws is essential for their performance. The diameter determines the amount of material the screw will displace when creating its own threads, impacting the strength of the joint. Screws come in various diameters, and selecting a size that matches the thickness of the materials being joined is crucial to ensure effective fastening.

Length is equally important; the screw should be long enough to penetrate both materials firmly without protruding excessively. Additionally, longer screws can provide more holding power, but they might also increase the risk of splitting thinner materials. Evaluating your project’s specific requirements and examining the materials’ thickness will help narrow down the ideal diameter and length for optimal results.

4. Head Style

Flat thread forming screws come with various head styles, each suited to different applications. Common head styles include flat, pan, and oval, which can be selected based on the aesthetic requirement and the function of the screw. Flat head screws are designed to sit flush with the material surface, making them ideal for applications where a smooth finish is necessary.

Head style can also influence the type of driver used for installation. Ensure you consider the available tools and how easily the screws can be driven in without causing damage to the surrounding materials. Depending on your application, the appropriate head style will provide the desired balance between functionality and appearance.

5. Drive Type

The drive type of flat thread forming screws is another key factor to consider for optimal performance and ease of use. Various drive types exist—including Phillips, slotted, and Torx—each offering distinct advantages. For instance, Phillips drives are common due to their self-centering action, which helps prevent the driver from slipping out during installation.

Selecting the best drive type also affects how much torque can be applied without stripping the screw head. If your application requires high torque, opting for a drive type that offers greater grip, such as Torx, is advisable. Consider the tools you have available and how much torque you need for installations when selecting the appropriate drive type for your screws.

6. Compatibility with Materials

Another essential factor when choosing flat thread forming screws is their compatibility with the materials you will be working with. These screws are designed to work effectively with a variety of substrates, including plastics, soft metals, and wood. Understanding the composition of your materials is critical to ensuring that the screws achieve maximum grip and holding power.

For instance, using flat thread forming screws in soft metals requires careful attention, as overtightening can lead to deformation. If you’re working with plastic materials, consider screws specifically designed for that purpose, which have features such as modified threads to enhance their performance. Evaluating the material compatibility will help you achieve a successful assembly without compromising the integrity of either the fastener or the substrates involved.

FAQ

What are flat thread forming screws?

Flat thread forming screws are specialized fasteners designed to create threads in materials such as plastics, metals, or composites without the need for pre-drilled holes. Unlike standard screws, they utilize a unique thread profile that displaces material rather than cutting, which helps in forming a stronger bond and ensures a tighter fit. This feature makes them ideal for applications where minimizing stress on the material is crucial.

These screws are particularly useful in assembly processes where quick and efficient fastening is required. They help in reducing the likelihood of stripping and provide better resistance to vibration and pull-out, making them suitable for automotive, electronics, and other industrial applications. Additionally, flat head designs allow for a flush finish, contributing to a cleaner aesthetic and minimizing obstructions.

What are the advantages of using flat thread forming screws?

One of the primary advantages of flat thread forming screws is their ability to create strong, secure joints without the risk of material deformation. This is crucial when working with softer materials that may be susceptible to damage from traditional cutting screws. The design also reduces the need for additional tooling, leading to expedited assembly times and cost-effectiveness in manufacturing processes.

Another significant benefit is their versatility. Flat thread forming screws can be used in a variety of materials and applications. They perform exceptionally well in high-vibration environments, providing excellent resistance to loosening over time. Their design also allows for easy installation and removal, making maintenance tasks simpler and reducing downtime in production lines.

What materials can flat thread forming screws be used with?

Flat thread forming screws are versatile fasteners, suitable for a wide array of materials, including various plastics, aluminum, and mild steels. Their unique design allows them to form threads effectively in materials that might not be compatible with standard screws. This capability makes them an excellent choice for industries such as automotive, aerospace, and electronics where a diverse range of materials is used.

When selecting flat thread forming screws, it’s important to consider the specific properties of the target material, such as thickness, hardness, and resilience. Some screws are specifically designed for softer materials, while others can handle tougher substrates. Understanding the compatibility of screw materials with the base material ensures optimal performance and longevity.

How do I choose the right size of flat thread forming screws?

Choosing the right size of flat thread forming screws involves considering several factors, including the thickness of the material, the tensile strength required, and the specific application. It is essential to refer to manufacturer guidelines and specifications, which provide recommended sizes based on the material type. Accurate size selection not only ensures effective fastening but also maintains the integrity of the components being joined.

In addition to length and diameter, other dimensions such as thread pitch may also play a crucial role in achieving the desired joint strength. When in doubt, it is advisable to consult with a fastener expert or the supplier’s technical resources to determine the most suitable screw dimensions for your project. This attention to detail can significantly influence the performance of the fastened joint.

Can flat thread forming screws be reused?

Flat thread forming screws are designed for optimal initial insertion and fastening performance; however, their reusability can vary depending on several factors. If they are installed and removed correctly without damaging the threads, they can often be reused in the same material. This is particularly important in applications where frequent maintenance is required. Care must be taken during removal to avoid stripping or damaging the threads formed in the material.

However, the longevity of reusable screws also depends on the material’s condition. If the host material shows signs of wear or the threads have become loose, reuse may compromise joint integrity. In cases where screws are removed frequently, it may be beneficial to conduct periodic inspections to determine if replacement is necessary, ensuring reliable connection strength in ongoing applications.

What tools are required for installing flat thread forming screws?

Installing flat thread forming screws typically requires a standard screwdriver or a power drill equipped with the appropriate bit. It’s essential to ensure that the bit matches the screw head type, whether it be Phillips, slotted, or another format. For automated assembly, specialized tools designed for thread forming can be used to enhance efficiency and accuracy, especially in high-volume production environments.

Additionally, depending on the material and application, it may be wise to employ a torque wrench to achieve the specified torque settings recommended by the manufacturer. Ensuring proper torque levels prevents issues such as stripping or overtightening, which could compromise the integrity of both the screw and the material. Understanding the installation requirements ensures longevity and optimal performance of the fastened joint.

Where can I purchase flat thread forming screws?

Flat thread forming screws can be purchased through a variety of channels, including hardware stores, industrial supply companies, and online retailers. Many specialized fastener suppliers offer a wide selection of thread forming screws in different materials, sizes, and head types, allowing customers to find the best match for their specific needs. Online platforms often provide the convenience of comparing products, reading reviews, and checking stock availability.

In addition to typical retail outlets, manufacturers may also sell directly to consumers or businesses. For bulk purchases or specialized applications, contacting the manufacturer directly can be beneficial as they may provide tailored advice, pricing, and even custom solutions for distinct requirements. Engaging with knowledgeable suppliers or manufacturers can greatly assist in making informed choices regarding flat thread forming screws.

Final Thoughts

In conclusion, selecting the best flat thread forming screws is crucial for achieving reliable and secure connections in your projects. Their unique design allows for efficient assembly and improved performance, especially in materials where traditional screws might struggle. By considering factors such as material, thread design, and application compatibility, you can ensure that you make an informed choice that meets your specific needs.

As you navigate through the various options available in the market, remember that investing in high-quality flat thread forming screws will not only enhance the longevity of your assemblies but also reduce maintenance and replacement costs in the long run. We encourage you to review our top picks and buying guide to find the best flat thread forming screws that will provide you with the durability and efficiency required for all your fastening tasks. Take the step towards optimizing your projects today!